The pig manure compost turner is a type of fermentation and compost turning equipment supplied by Zhengzhou Chengxiang Heavy Industry for global organic fertilizer production lines. As a professional fertilizer equipment manufacturer with 30 years of experience, we offer four types of compost turning equipment: crawler-type compost turners, small wheel-type compost turners, hydraulic trough compost turners, and large impeller compost turners. Below is an introduction to the hydraulic trough compost turner used in pig manure production lines.

1. Applications of Pig Manure Turners

Pig manure turners are used to ferment and compost organic waste such as livestock manure, sewage sludge, sugar factory filter mud, residue cake, and straw sawdust. They are widely used for fermentation, decomposition, and water separation in organic fertilizer plants, compound fertilizer plants, sewage sludge plants, horticultural farms, and Agaricus bisporus cultivation. They can also be used as bio-organic fertilizer fermentation equipment.

This pig manure turner is suitable for aerobic fermentation and can be used in conjunction with a solar-powered fermentation chamber, fermentation tank, and transporter. When used with a mobile unit, it can achieve multi-tank functionality. The accompanying fermentation tank can discharge materials continuously or in batches. It features high calibration, stable operation, durability, and uniform turnover.

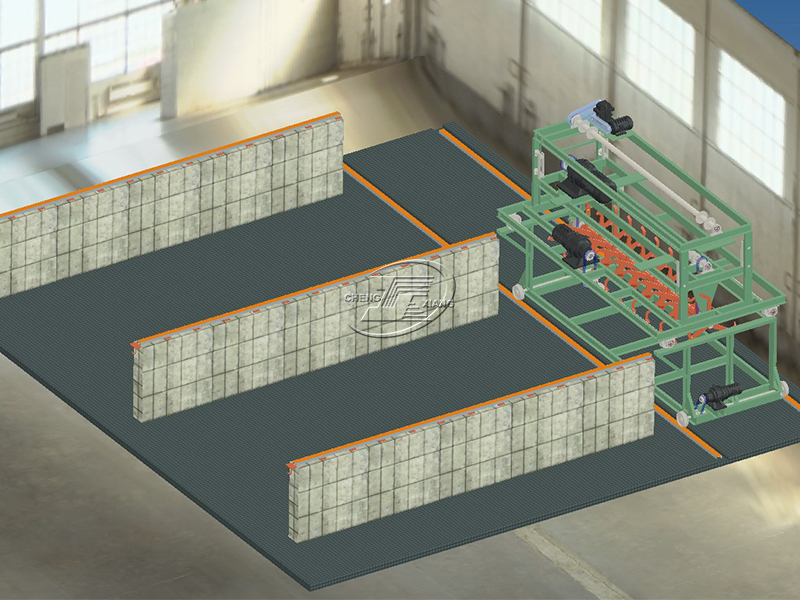

2. Overview of the Pig Manure Turner Structure

The pig manure trough fermentation turner consists of a transmission, lifting device, travel mechanism, tipping mechanism, and transfer vehicle. The motor transmits power directly to the cycloidal pinwheel, which in turn drives the tipping drum via a sprocket. The drum’s tipping wings, arranged in rows, stir and rotate the material in the fermentation tank, moving it backwards. This achieves rapid tipping and uniform mixing, ensuring a high-quality, air-to-material impact, resulting in a more efficient fermentation process. The control cabinet is centralized and supports both manual and automatic control. Equipped with a soft starter, it reduces shock loads during startup. The gears are durable and provide a certain degree of material crushing and mixing.

3. Working process of pig manure turning machine

(1) Put the raw materials into the feed port every day;

(2) The equipment stirs the raw materials to the outlet every day, and the journey is the same every day;

(3) After 30 days of fermentation, the fermented raw materials are completely decomposed and converted into organic fertilizer;

(4) After a period of aerobic fermentation, finished organic fertilizer can be obtained from the outlet every day, forming a circular fermentation process of fertilizer.

Warm Tips: Adding a certain amount of organic fertilizer fermentation agent before fermentation can greatly shorten the fermentation time of the raw materials, improve the fermentation efficiency, make the fermented organic fertilizer contain more organic matter, and improve the utilization rate of organic fertilizer.

4. The role of pig manure turning machine in organic fertilizer production

The trough fermentation turning machine is a commonly used aerobic dynamic composting equipment. As a new type of machine, it has rapidly proliferated in the family of organic fertilizer equipment and has become a handheld machine that replaces manual and forklift turning of materials. It is a common product that affects the development trend of the composting industry.

(1) Mixing function in raw material adjustment. In fertilizer manufacturing, in order to adjust the carbon-nitrogen ratio, pH value and water content of the raw materials, some auxiliary materials need to be added. The main raw materials and various auxiliary materials are roughly piled together in proportion and can be evenly stirred by a turning machine to achieve the purpose of conditioning.

(2) Adjust the temperature of the raw material pile. During the operation of the turning machine, the raw material particles are in contact with and mixed with the air, and the pile can accommodate bright fresh air, which helps aerobic microorganisms to actively generate fermentation heat and increase the temperature of the pile; when the temperature is high, adding fresh air can reduce the reactor temperature. It forms an alternating state of medium temperature-high temperature-medium temperature-high temperature, and various beneficial microorganisms grow and reproduce rapidly within the temperature range they are adapted to.

(3) Improve the permeability of the raw material pile. The turning system can process the material into small pieces, making the sticky and dense raw material pile fluffy and elastic, forming a suitable porosity.

(4) Adjust the moisture content of the raw material pile. The suitable moisture content of the raw material fermentation is about 55%, and the moisture content standard of the finished organic fertilizer is below 20%. During the fermentation of pig manure, biochemical reactions produce new water, and the consumption of raw materials by microorganisms also causes the water to lose its carrier and free water. Therefore, during the fertilizer production process, the moisture content will decrease in a timely manner. In addition to evaporation caused by heat conduction, the turning of raw materials by the turning machine will form forced water vapor emission.

(5) To meet the special requirements of the composting process. For example, crushing the raw materials to give the raw material pile a certain shape or to achieve quantitative replacement of raw materials.

Zhengzhou Chengxiang Heavy Industry Organic Fertilizer Equipment Ordering Process

Pre-sales Service: We provide project design, process flow design, and a customized fertilizer equipment procurement plan. We design and manufacture fertilizer equipment according to your needs, and provide technical operator training.

Sales Service: We accompany you through equipment acceptance and assist in developing a construction plan and detailed procedures.

After-sales Service: We dispatch technicians to guide on-site equipment installation and commissioning, provide operator training, and offer a long-term warranty.

Our fertilizer equipment includes organic fertilizer production lines, compound fertilizer production lines, blended fertilizer production lines, and the aforementioned standalone fertilizer equipment. We welcome customers worldwide seeking fertilizer equipment to contact us for product inquiries. We will provide our utmost service and help you select the right fertilizer equipment for your needs.