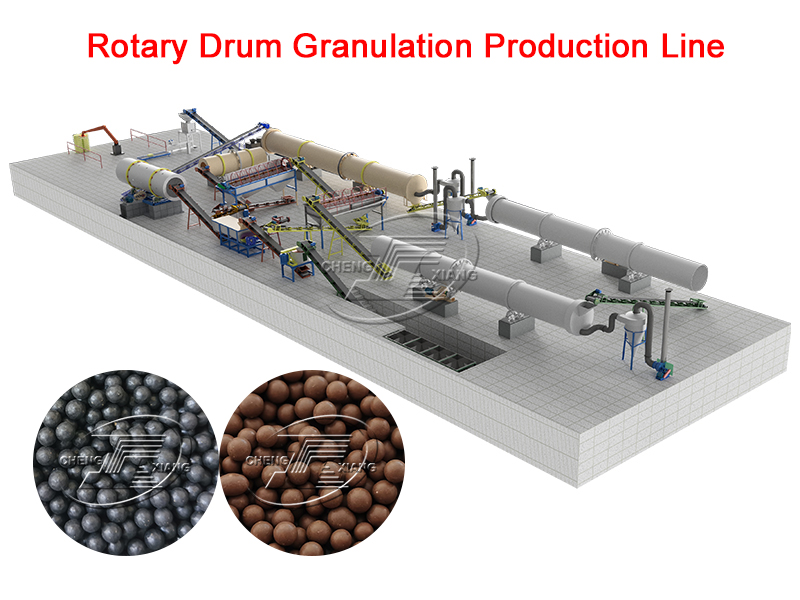

The rotary drum granulator is one of the organic fertilizer granulation equipment from Zhengzhou Chengxiang Heavy Industry, a professional organic fertilizer manufacturer. It has the characteristics of low cost, good granulation effect, energy saving, and labor saving. It is widely used by most customers for granulation of poultry manure and compound fertilizer granulation production lines.

Zhengzhou Chengxiang Heavy Industry is located in Zhengzhou, Henan, China. As a fertilizer equipment manufacturer with over 28 years of factory history, our factory is confident in providing you with professional, efficient, and environmentally friendly fertilizer equipment and sincere after-sales service.

Below we will introduce one of our fertilizer production equipment – the rotary drum granulator

Rotary Drum Granulator For Sale

Rotary drum granulator is a machine which can granulate materials into specific shapes. It is suitable for large scale production of cold, hot granulation and high and low concentration complex fertilizer. What’s more, it is one of key facilities to make compound fertilizer, You can equip with other machines to form a complete compound fertilizers production lime, Our company provides you complete supporting facilities including batchimg machines, screeners, blender and so on.

The rotary drum wet granulator can produce not only compound fertlizers, but also organic fertlizer as the disc pan granulator machines. Meanwhile, it also uses wet granulation method. Ifyou want to make fertlizer with dry granulation method, we can provide you double roller press granulator for dry granulation. And we also have new organic fertilizer granulator for making pure organic fertilizers if you need.

Why Choose Rotary Drum Granulator?

Rotary drum granulator overcomes the defects of disc granulator including the low production, low strength of finished granules and so on. Moreover, when you are making compound fertilizer by disc pan granulator,it’s diffcult for you to add some steam in. Rotary drum granulator machine realizes this production technology.

Comparing with pan granulator, Rotary drum granulator is more suitable for large scale produchion.Its output can reach 35 ton per hour. This can bring more economic eficiency to your fertilizer plant. Meanwhile,it doesn’t need too much labor force to operate it. If you want to get high ouput,high economic benefits and low labor force consumption, why not have a try on rotary drum granulator?

How Does The Rotary Drum Granulator Work?

This rotating pelletizer granulates pellets by centrifugal force. It rotates the cylinder. Then the powders will get together and become pellets. Do you know how each components work together? And how can you do for better granulating?

How Does Each Granulator Components Work Together?

The belt and pulley are driven by the main motor. Then the materials will get into the drive shaft through the reducer.The open gear which is installed on the drive shaft works together with the large gear ring. The gear ring is fixed on the body. With the special structure inside the cylinder,the raw materials can be granules and out through the outlet.

What Granulate Methods Does The Machine Employ?

Rotary drum wet granulator adopts the wet granulation method. With a certain amount of water or steam,there will be chemical reactions in the cylinder. The rotating of cylinder will make the materials squeeze, And then materials will become granules under a certain liquid condition.

How Can The Granulator Perform Better?

With vapour, gas ammonia, or phosphoric acid or nitrogen solution, phosphorous ammonia slurry, heavy calcium slurry,the materials can be with uniformity and humidity in the rotary drum. Thereupon, there will be chemical reactions and heating reactions in the tube. Finally, the finished fertilizer granules can be 3mm~4mm.

What Is The Fertilizer Drum Granulation Production Process?

Utilizing the drum rotating equipment for granulating,do you know the granulation process? Here we can show you the detailed granulation process for making fertilizer granules when you use drum granulator as granulation machine.

1.Before the granulation, you should make sure your materials are powdery. It is necessary for you to use powdery fertilizer as materials for drum granulation.If your materials are not fine for granulating, you had better apply a fertilizer crusher for making fine powdery fertilizer materials.

2.when you feed fertilizer powder into the granulation equipment the cylinder will he rotating and rotate the powders to granules. The pelleted fertilizers will he out when it becomes granules. Meanwhile, if you need, it is also applicable for you to add some vapour for pelletizing better.

3.After the granulation, you should dry the granulated fertilizers to make it more convenient for transporting and storing. There are drying and cooling machine for you to process them more efficiently.

Irresistible Reasons For You To Choose Rotary Drum Granulator Machine

1.Because of the high quality liner, the rotating granulator has long service life.

2.Its granulation rate can reach 75%. Moreover, the small granules are less. Even if there are unqualifed granules, you can granulate them again.

3.By improving the materials temperature with the vapour,the granules will have low moisture contents, At the same time, it improves the drying efficieney.

4.You can make different fertilizers by this machime,including high nitrogen compound fertilizer whose nitrogen content is above 20%, special fertilizers,organic-inorganic fertilizer and so on.

5.It can be widely used with varieties of raw materials. You can mix low solubility materials with high solubility according to the formula. Moreover,it is applicable to add some organic matter and microelement.

How To Maintain The Rotary Granulator To Make It Work Better?

You’d better use high quality lubricating oil on bearing,because it plays an important role on the machines’ running. It influences the service life of drum granulator machine. You should use lubricating oil on the following parts:

1.Rotating bearing

2.Roll bearing

3.All the gearwheel

4.Active bearing, sliding plane

5.Check the strake often because it is easy to be loose

Keep an eye on making sure whether all the parts of the machine work well or not, when rotary drum granulator machine is working. You must stop the machine in time, if you find the bearing oil temperature is raised. Then check and eliminate it, also for the gearwheel.

Oil these parts frequently to make sure the machine work better:

1.Scribble dry butter on gearwheel before the machine works

2.Wipe dry butter on the surface of rolling belt every 7 days.

3.Add gearwheel oil before the speed reducer works.

4.change the gearwheel oil every 4 months.

If you have any interest or demand for our products, please feel free to send us an inquiry at any time! Chengxiang Heavy Industry will provide you with a variety of services including site design, product matching and design, product supply, installation and after-sales service, and offer a one-stop service from design to installation.