Organic fertilizer granulator equipment is one of the most important organic fertilizer production equipment. It has a direct impact on the quality of granular organic fertilizer, and has a great relationship with the roundness, uniformity, and fertilizer and water retention of fertilizer granules. So, what are the differences in the production processes of various types of organic fertilizer granulators? What are the effects on the products?

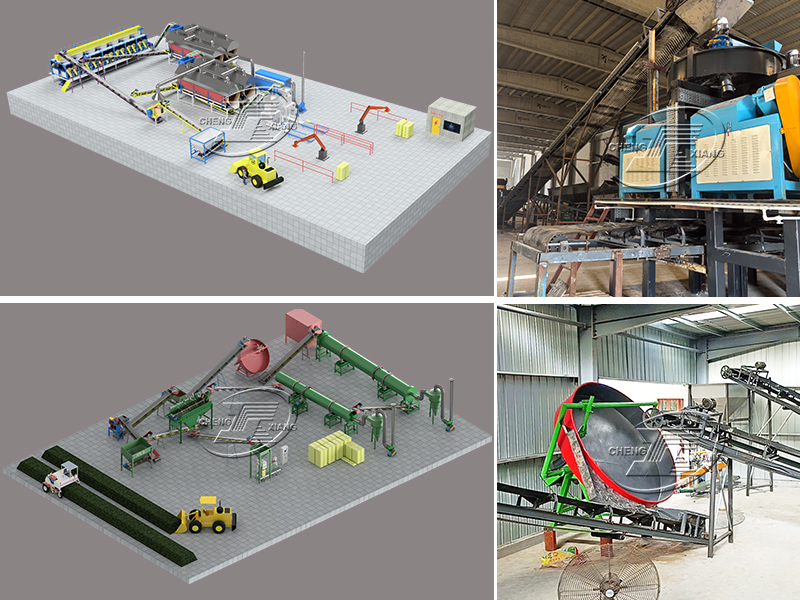

As a professional fertilizer equipment manufacturer, Zhengzhou Chengxiang Heavy Industry will introduce to you: the different characteristics and respective advantages of the two granular organic fertilizer processing processes of disc granulator production and roller extrusion granulator.

1. Comparison of production processes and advantages of disc granulator and extrusion granulator

In terms of the classification of granulator processes between the two, the disc granulator belongs to the granulation process using centrifugal force, while the extrusion granulator belongs to the roller granulation process.

The following is a description of the two processes. The initial fermentation process of organic fertilizer is the same, that is, livestock and poultry manure is fermented in a fermentation tank with appropriate auxiliary materials. The process after fermentation and composting is different, and the difference starts from the process after fermentation and composting of organic fertilizer.

2. Comparison of the process flow of organic fertilizer production line of disc granulator and roller extrusion granulator

Process flow of organic fertilizer production line of disc granulator:

(1) Crushing and mixing: The fermented and decomposed animal powder organic fertilizer raw materials are crushed to achieve the appropriate granules size, and then transported to the horizontal mixer for mixing. After mixing evenly, it is transported to the granulator feed bin. Chengxiang Heavy Industry can provide you with: fertilizer crusher and mixer.

(2) Feeding and granulation: The powdered raw materials are evenly fed through the feeding bin and fed into the disc of the disc granulator at a uniform speed; according to the moisture content of the material, the moisture is sprayed on the surface of the material in the disc through the automatic moisture sprinkler of the disc granulator to make the powder reach a reasonable humidity; the powder uses the centrifugal force of the disc rotation and the friction of the disc to produce axial rolling. During the rolling process, the powder granules are rubbed and squeezed to form organic fertilizer granules with relatively high moisture content. Chengxiang Heavy Industry can provide you with: feeder and disc granulator.

(3) Drying and cooling: The processed moisture-rich granules are transported to the organic fertilizer drum dryer through a belt conveyor. During the tumbling process of the granules in the dryer, they are converted into heat energy blown from the hot air furnace to achieve drying. After the granular organic fertilizer is dried to a reasonable moisture content, it is transported to the cooler, where it is quickly cooled down. The cooled granules are sent to the screening machine to achieve granules classification. Chengxiang Heavy Industry can provide you with: dryer and cooler.

(4) Screening and coating: In the drum screening machine, qualified organic fertilizer granules are sent to the coating machine via a conveyor for coating; unqualified granules are sent back to the crushing and mixing process for granulation. Chengxiang Heavy Industry can provide you with: screening machine and coating machine.

(5) Packaging and warehousing: The coated granules are measured and packaged by a fully automatic weighing and packaging scale, and then put into storage. Chengxiang Heavy Industry can provide you with: packaging machine and palletizer.

(6) Dust removal process: Drying, cooling and workshop dust disposal, using cyclone dust collector or water curtain wet dust removal three-level treatment, and emptying after meeting the standards. Chengxiang Heavy Industry can provide you with: dust collector.

Extrusion granulation granulator organic fertilizer production line process:

(1) Crushing and feeding: The mature and qualified raw materials with moderate humidity are transported to the high-efficiency mixer according to the ratio, mixed in the high-efficiency mixer, and the mixed materials are sent to the disc feeder.

(2) Feeding and granulation: In the powder disc feeder, the powder is evenly fed to the extrusion granulator. During the process of passing through two rollers, the powder is pressed into granules by the two semi-concave spheres on the rollers. Then the processed granules are sent to the next process via a belt conveyor. Chengxiang Heavy Industry can provide you with: disc feeder and roller extrusion granulator.

(3) Screening and packaging: After the organic fertilizer granules enter the screening machine for screening, the fine ones are directly returned to the extrusion granulator for granulation, and the large granules are returned to the crusher for feeding and granulation. The qualified granules are transported to the fully automatic packaging scale for measurement, packaging and storage.

3. Comparison of the process advantages of disc granulator and roller extrusion granulator for organic fertilizer production line

Advantages of disc granulator for processing organic fertilizer production line

(1) The disc granulator can directly observe the real-time granulation situation. If the granulation process is abnormal, it can be adjusted at any time.

(2) The granules size can be adjusted, and the degree of freedom is relatively large. This is because the size of the granules depends on the inclination angle and rotation speed of the disc. The disc granulator can adjust its inclination angle and rotation speed, so the granules size control range is relatively wide.

(3) The disc granulator organic fertilizer production line has a short process flow, a simple process structure, and relatively low equipment investment, which is more suitable for small and medium-sized enterprises.

Process advantages of the roller extrusion granulator organic fertilizer production line:

(1) The roller extrusion granulator belongs to dry granulation. It does not need to adjust the dryness and wetness of the material during granulation, and does not need to add drying equipment.

(2) The granulation range is wide. It can be adapted to the processing of granules containing heat-sensitive materials, such as organic fertilizer granulation with ammonium bicarbonate.

(3) Because it is a dry granulation, no wastewater or waste gas is discharged during the production process.

(4) The extrusion granulation process is short, easy to automate, and the production efficiency is relatively high.

(5) The roller extrusion granulator has good production flexibility and can adjust the fertilizer production plan at any time. It can be used to produce organic special fertilizers and compound fertilizers.

(6) Compared with pelletizing, the granules size uniformity of the roller extrusion granulator has a greater advantage, because the spherical pits of the rollers are of the same size, and a variety of roller skins can be matched for customers to produce granules of different shapes.

From the comparison of the processing technology and advantages of the above-mentioned disc granulator and roller extrusion granulator organic fertilizer production line, we can see that there are differences in the processing of granular fertilizers. The disc granulator has a high degree of freedom in granules size and good smoothness and roundness, while the roller extrusion granulator has a relatively uniform granules size. From the production process, the processing technology of both is not too complicated. The roller extrusion granulator is simpler to granulate and has no requirements for material humidity.

As a professional fertilizer equipment manufacturer, Chengxiang Heavy Industry can provide you with professional fertilizer (organic fertilizer, compound fertilizer, blended fertilizer) production line equipment, and design plant and equipment layout drawings for you. After providing the equipment, there are professional installers to install and debug it for you until the production process goes smoothly. Our factory has always insisted on serving various customers at home and abroad with professional technology and honest attitude. As a field manufacturer with more than 15 years of export experience, we have customers all over the world and provide professional fertilizer production cases for our customers and friends. If you need fertilizer equipment, you are welcome to visit our factory and discuss cooperation.