With the progress of the times, agriculture has also developed rapidly, and green environmental protection has become one of the standards. In agriculture, converting waste such as animal manure into valuable fertilizer has become one of the effective ways to solve green agriculture. So how to efficiently convert animal manure into fertilizer? Today, Zhengzhou Chengxiang Heavy Industry, a professional fertilizer equipment manufacturer, will explain to you. If you need fertilizer equipment to produce efficient and high-yield animal manure granules, you can consult our factory.

Introduction to chicken manure fertilizer production line

Chicken manure granular fertilizer production line is a key link in modern organic fertilizer production, converting poultry manure into high-value granular fertilizer. This advanced fertilizer production system solves environmental problems and meets agricultural needs by converting untreated manure into uniform and easy-to-handle fertilizer granules.

Process flow of chicken manure granular fertilizer production line

1. Raw material collection and processing: fermentation equipment and crushing equipment

The fertilizer production process begins with the collection of fresh chicken manure. The raw materials go through the following processes: solid-liquid separation using a screw press; moisture adjustment to an optimal level of 45-55%; fermentation using a dedicated microbial strain; crushing and screening to ensure uniform particle size

2. Granulation technology and selection of fertilizer granulators

Modern fertilizer production lines offer a variety of granulation methods, and you can choose one of them:

(1) Drum granulation line: high-capacity continuous processing; suitable for large-scale fertilizer production; produces 2-5 mm spherical particles; low energy consumption.

(2) Disc granulation line: adjustable disc angle to control particle size; lower energy consumption (15-20 kWh/ton); suitable for small and medium-sized fertilizer plants; produces 3-8 mm particles.

(3) New granulation line (three-in-one granulation line): specially designed for sticky organic matter; high granulation rate (>95%); low moisture requirement; less return material.

3. Drying and cooling system: dryer and cooler

Chicken manure granular fertilizer production line includes: rotary dryer with hot air furnace, suitable temperature control; equipped with rotary cooler, rapid cooling; moisture content is reduced to below 15%.

4. Screening system and coating system: screening machine and coating machine

Vibration screen to select qualified particles; automatic coating machine to apply protective layer; polishing particles to improve appearance.

5. Packaging automation system: automatic packaging machine

Weighing and bagging system; sewing or heat sealing options; palletizing robot for bulk handling.

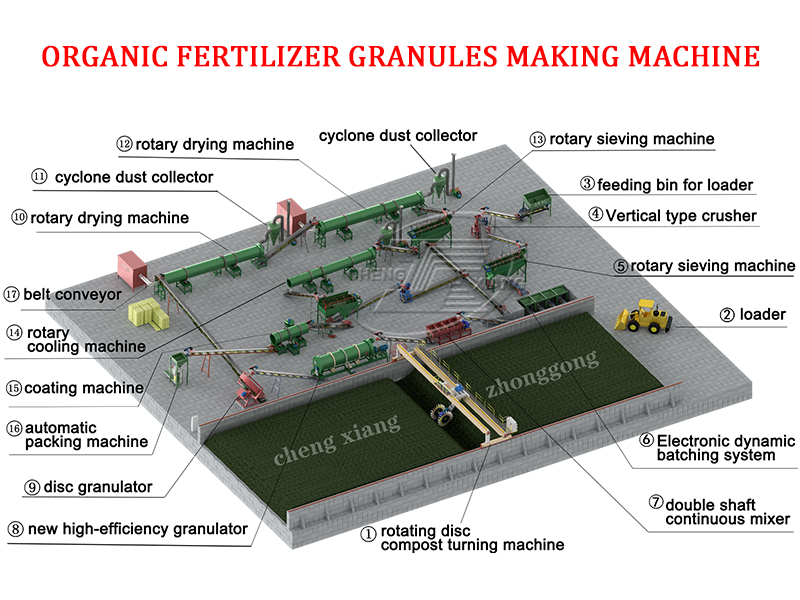

Key equipment of chicken manure granular fertilizer production line

As a professional fertilizer equipment manufacturer, the following equipment is the key equipment of chicken manure granular fertilizer production line. Zhengzhou Chengxiang Heavy Industry can provide you with professional equipment and installation and after-sales service.

1. Compost turner: accelerate the fermentation process. Mainly including: hydraulic lifting trough compost turner, crawler compost turner, wheel compost turner, large impeller disc compost turner.

2. Crusher: prepare uniform raw materials for granulation. Mainly include: vertical crusher, semi-wet material crusher, urea crusher, chain crusher, hammer crusher.

3. Mixer: ensure the uniformity of chicken manure raw materials. Mainly include: horizontal mixer, double-shaft continuous mixer, vertical disc mixer.

4. Granulator: the core of fertilizer production. Mainly include: disc granulator, drum granulator, three-in-one granulator, stirring tooth granulator.

5. Dryer/cooler: stabilize product quality, dry and cool chicken manure pellets. Mainly include: rotary dryer, rotary cooler.

6. Screening machine: quality control, screening qualified chicken manure pellets. Mainly include: shaft drum screening machine, shaftless drum screening machine.

7. Coating machine: improve product performance and make chicken manure pellets have a better appearance.

8. Packaging system: finished product processing, bagging, sealing and palletizing.

Advantages of chicken manure granular organic fertilizer

1. Waste utilization: convert environmental pollutants into valuable resources

2. High nutrient concentration

3. Improve soil structure: increase organic matter (≥60%)

4. Controlled release: slowly release nutrients to meet plant needs

5. Reduce odor: granulation can greatly reduce odor

6. Convenient application: uniform particle size, easy to mechanized spreading

Chicken manure granular production line represents an advanced fertilizer production solution that combines environmental sustainability with agricultural productivity. As organic agriculture continues to expand around the world, investment in advanced fertilizer production technology will bring ecological and economic returns. Future development will focus on increasing automation, improving energy efficiency, and improving product quality through innovative granular technology.

Chengxiang Heavy Industry has been committed to fertilizer production equipment for more than 30 years, exporting for more than 13 years, serving thousands of foreign customers, and is a powerful fertilizer equipment manufacturer in China. Our factory supplies you with fertilizer equipment including: organic fertilizer production line equipment, compound fertilizer production line equipment, blended fertilizer production line equipment, and various supporting equipment such as crushers, screening machines, dryers, coolants, batching machines, packaging machines, film coating machines, forklift loading silos, etc. We provide you with comprehensive pre-sales, in-sales, and after-sales services, and have become a partner of many fertilizer manufacturers.

We are located in Xingyang, Zhengzhou City, Henan Province, China. If you need professional and efficient fertilizer equipment, please consult Zhengzhou Chengxiang Heavy Industry, and you can come to our factory for inspection and cooperation.